William Buel: Printing for the pandemic

When the COVID-19 outbreak established its hold in the Houston area, medical professionals and facilities joined the plight of their peers around the world for PPE. Gov. Greg Abbott even called upon newly trained, soon-to-be-certified, and retired nurses to join the front lines of the pandemic combat. Little did San Jacinto College engineering design graphics instructor William Buel know he would be part of this effort as well.

In April, San Jac, Houston Community College, University of Houston at Sugar Land, Fort Bend County Judge's Office, TX/RX Labs, Alief ISD, and Houston ISD joined efforts to help address PPE shortages for local area medical professionals and first responders in the fight against COVID-19. The collaborative effort known as H-Force is a comprehensive community partnership platform bringing together members' resources, technologies, and expertise to address the Houston area's growing needs amid the global crisis.

Buel is the project manager for the College's H-Force contribution, which included using 30 of its 3D printers to create face shields to help alleviate the local PPE shortage. In addition to the H-Force collaboration, the College is printing 900 extra face shield headbands for CHI St. Luke's Health Patients Medical Center in Pasadena and its affiliate in Sugar Land, Harris County, City of Houston Veterans Affairs offices, and several other medical and academic facilities. According to Buel, leading the San Jac team has been rewarding on many levels. He answers questions about the experience:

Q: How did you become involved in the College's efforts with the H-Force partnership?

A: When San Jacinto College administrators started thinking about joining this project, South Campus dean of business and technology Kevin Morris recommended me to head the project based on my background in manufacturing and production.

Q: Are other faculty and students involved?

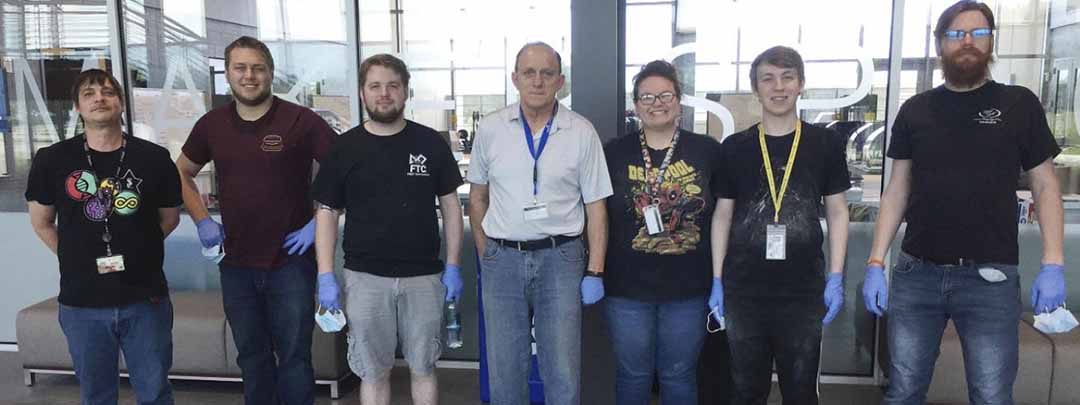

A: Yes, we have a great team, which includes Dr. Christopher Wild, department chair of physical sciences; Jeff Robison, chemistry lab supervisor; James Isaacks, computer information technology adjunct faculty and daytime project supervisor; Scott Vlasek, construction management professor and evening supervisor; Clarissa Belbas, LyondellBasell CPET director; Sami Yu, part-time chemistry staff; Bang Nguyen, part-time physics specialty lab assistant; and student assistants Tanner Cates, Jose Amieva, Thomas Gullick, and Jack Yu. I can't say enough great things about all the work our team has been doing to help in these efforts.

Q: Given that this pandemic is unlike anything we've seen before, how do you feel your previous professional experience and current teaching experience prepared you to lead the College's team for this project?

A: Although we had to work quickly, the requirements for setting up this manufacturing facility and operations are the same as most other manufacturing operations I have been responsible for. This included establishing and operating plans for evaluating the need, getting the equipment, developing processes, getting required skilled personnel, scheduling and running production, preparing necessary documentation, and shipping the product on schedule.

Q: In your opinion, how does this shed light on how engineering drafters/designers can be essential to a number of industries?

A: Prior to the pandemic, the College has been very supportive of the additive manufacturing efforts of our 3D print labs and teaching requirements to prepare students (several were involved technically in this project) for the design and operational requirements in the 3D printing industry. Everything we have been working on — from initial product development to shipping the final pieces — is allowing these students to see how their skills can be applied to any emergency situation that isn't necessarily what they pictured as drafting/designing jobs. It's also providing these students with unique hands-on experience that future employers will hone in on.

Q: How will this pandemic change the engineering drafting/designing industry?

A: I think this project highlights the need for more additive manufacturing directions in future classes with understanding that the world is changing more rapidly due to this pandemic. With proper preparation, our students can and will be at the forefront of future industry requirements in design and manufacturing.

Q: Going forward, how will this experience change or enhance what you teach your students?

A: As with Skills USA and other academic project competitions, we are always looking for ways to aid our students and help develop them into the leaders of tomorrow. As faculty, we have learned a lot about teaching remotely, and I hope our students are also seeing how easily technology can be harnessed and used as tools in these situations.

I especially want to thank San Jacinto College administrators for allowing my team to step up when the need was greatest and allowing us to show how the skills these students are learning are being used to make this world a better place. This project taught us all about giving more of ourselves to those we will never meet and saving more lives than we could ever imagine.